Every now and then - I am smitten by the toggle bug. Since it's a multi day/step product - often I have a day of making just rings - then time is spent pairing them up - and then comes the final torch day... yesterday was just that!

These are little sculptures that have movement - and color - plus a sweet clink sound as the rings tap each other. There is a bead hole through the main part of the spindle, and can be worn - I see these as more of a collectors' piece.

I had two kilns going at once, and this made things much easier - as one held soft glass beads and the other had the borosilicate components for these toggles. There is always a ramp up *in my psyching myself up* to get 'em done... and finally by day's end - I was there. Happily pleasing results!! smiles, Jill

4.23.2014 - Spirals & Stringers

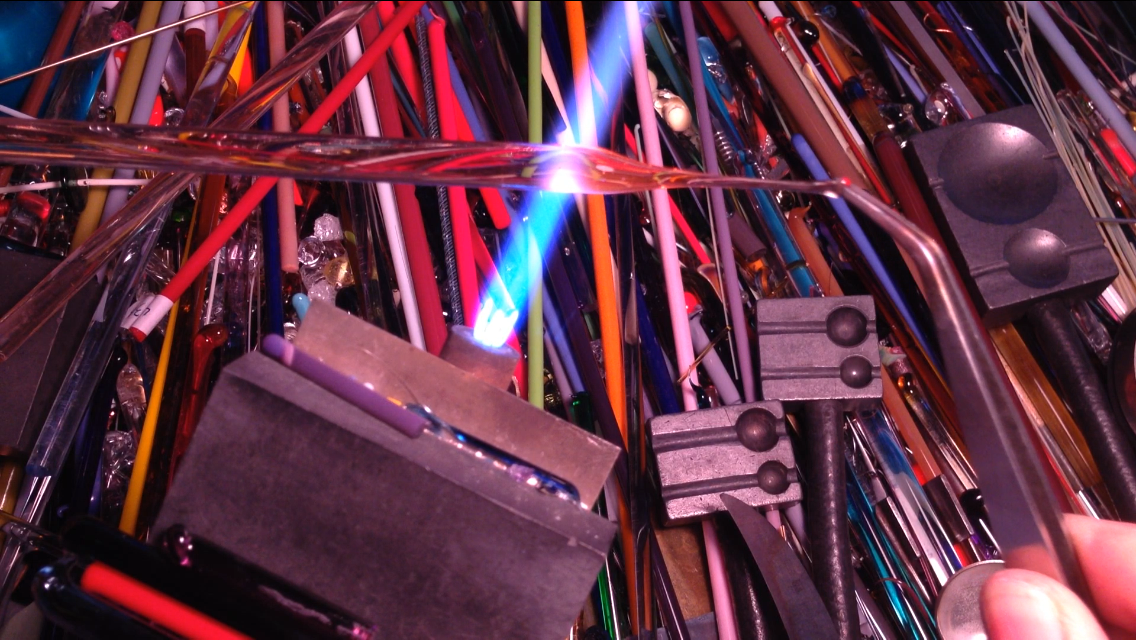

I got to thinking about the wound spirals I make, and thought oh - it's because I use boro stringers - that all have a nice consistent diameter. Well, that's true for the clear - but the colored ones are made from rods - I like to pull from 7-8mm dia. rods. As I pull the stringer, it's spiraled up on the other side of the torch. Feed boro in from the front of the torch - mandrel in back, catching the stringer and winding it up. Does that makes sense to you?

That got me to thinking about how new lampworkers are taught to pull stringers. I've heard about heating a rod in the middle and pulling out each end with the stringer in the middle. Or puntying on with a stainless steel chopstick. I think Corina was just talking about how not to use tweezers, because the stringer retains the tweezer shape for a couple of inches in initial pull stages - and how that can get to be expen$ive if it's silvered glass your'e tossing away!

When I need a length of stringer, I pull using needle nose pliers...

I fix my eyes about 1 1/2" to the right of the flame. I slowly feed a thick rod from the left and pull to the right... always watching that same check spot 1 " to the right of the flame. I pull about an inch, then let the glass slightly chill and set the diameter to what I need... once that's been established, I can control the speed at which the glass is fed into the flame from the left and simultaneously control the speed & temperature of the glass I'm pulling from the right.

Do I have a stringer stash? Sheesh... I wish, but cataloging yet another thing is not in my mental makeup. There is a sense of freedom pulling fresh ones each time!